At Ace World Companies, we’ve engineered and manufactured overhead cranes and lifting equipment for decades. We understand that the backbone of any efficient crane system lies in its end trucks – the components that guide and support the bridge as it travels along the runway.

Whether you operate a small workshop or a massive industrial facility, the right end trucks are crucial for safety, performance, and longevity. That’s why we offer a comprehensive range of standard and custom end truck solutions designed to meet the unique demands of your specific application.

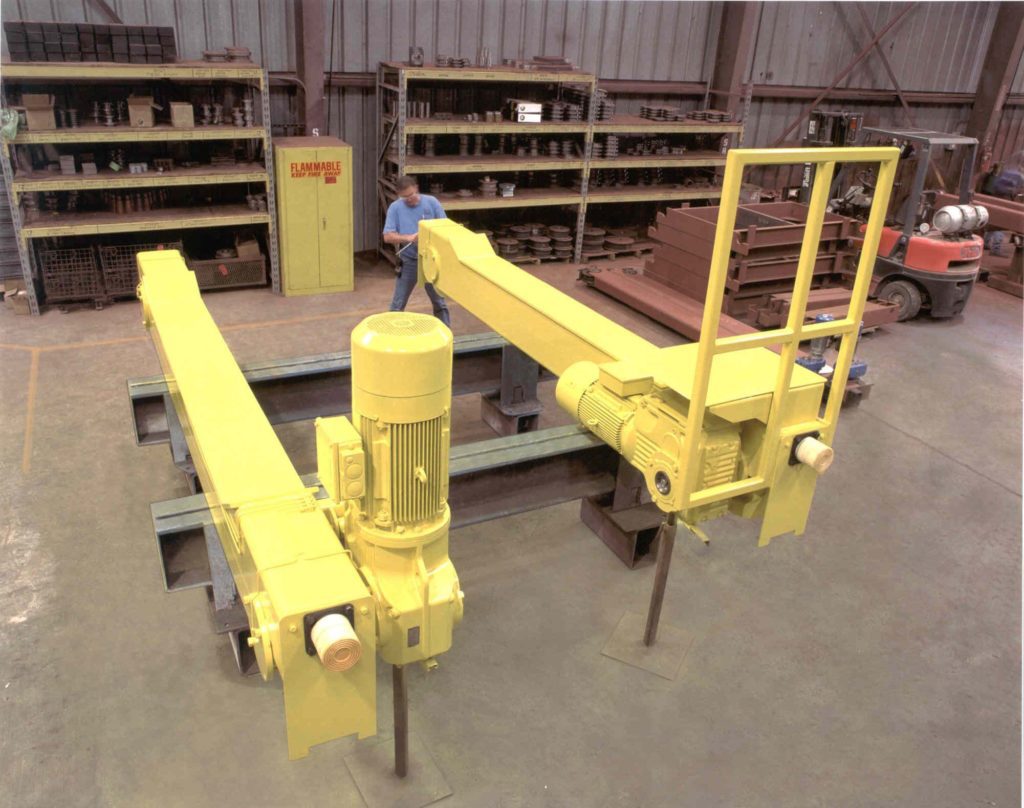

We offer standard end trucks with 3-50 ton capacities in various designs. These cost-effective solutions are ideal for typical crane applications and come equipped with many standard features to ensure smooth and reliable operation. However, we understand that not all projects fit a standard mold. That’s where our custom end truck expertise comes in. We can create end trucks for virtually any application, with capacities exceeding 1,000 tons. Our in-house capabilities allow us to build some of the largest end trucks in the industry, and we thrive on the challenge of creating unique solutions tailored to your exact specifications.

We offer a full line of standard-end trucks, with capacities ranging from 3 tons to 50 tons. Our trucks are cost-effective and include many standard features. Click on the link below to see some of the capacities and standard features we have to offer. To request a quote click on the “Request A Quote” link below and answer a few questions about your crane and we will find the right pair of end trucks for you. It’s that easy!

Standard Capacities & Features

We design and manufacture end trucks for all applications up to 1,000 tons or more. We have the in-house capability to build some of the largest end trucks out there, and there is no limit to what we can do! Most manufacturers offer standard-end trucks only, and will not deviate from the norm. With us, it doesn’t matter what you need because we can do it.

DESIGN FEATURES:

For a full understanding of our offering, please visit our End Truck Photo Gallery to view some of our past projects

The correct bridge crane end trucks depend on your operation. Ace World Companies offers end trucks in various configurations to suit your specific crane setup and operational needs:

No matter what type of crane you operate or the specific challenges of your application, we have the end truck configuration to meet your needs. Our team can help you select the right end truck to maximize your crane’s performance and lifespan.

Ready to optimize your crane’s performance with the perfect end trucks? Our experienced team is ready to discuss your needs and provide expert guidance. Call us at 800-431-4223 to learn more about our full range of standard and custom end truck options. Or, request a quote online to get started on your custom solution today. Let Ace World Companies be your partner in maximizing your crane’s efficiency and safety.