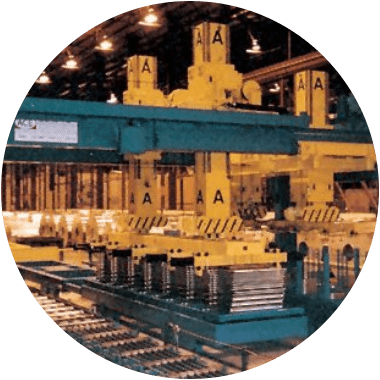

Ace World Companies manufactures overhead bridge cranes ranging in capacities from 5 tons to 500 tons or more and in spans to meet your needs. We have been in business for over 30 years and have manufacturing facilities in both Fort Worth Texas, and Clinton Tennessee. Our line of cranes includes Single Girder Top Running Bridge Cranes, Single Girder Under Running Bridge Cranes, and Double Girder Top Running Bridge Cranes. From simple to some of the most sophisticated equipment in use today, we design and manufacture all types of cranes for all types of applications.

Why choose Ace World Companies to design and manufacture your overhead bridge crane? We have in-house engineers who can design and customize a bridge crane that will be the best fit for your application. Our knowledgeable sales staff is willing to meet you, look at your facility, and discuss your material handling needs. Because of this, we will offer you a solution based on your needs and this will make your facility more productive and safe. Ace World Companies boasts an 80,000-square-foot machine shop. We manufacture the parts for our cranes and hoists, so this enables us to control the quality of the parts going onto your crane as well as lead times for spare parts.

Overhead bridge cranes are used to move heavy and cumbersome loads from point A to point B in your facility. When choosing an overhead bridge crane it is important to consider both the present and future operations of your business. You need to know at what capacity your crane will be lifting, and how often you will be lifting and moving the load. These questions will be used in determining what type of overhead crane you will need, the service class of your crane as well as the crane capacity. The proper service class is a must to reduce the wear and tear on your crane as well as extend the life of the crane.

Consists of one beam that is supported by end trucks on each side of the beam. The trolley and hoist are mounted on the bottom flange of the beam. This type of crane has a reduced hook height as compared to the double girder crane. The single girder crane is less expensive because it consists of only one girder as compared to the double girder crane.

Single girder top running cranes – These overhead cranes are ideal in light service situations where your load will be no more than 20-25 tons and the span of this overhead crane should be 65’ or less. The bridge girder runs along the top of the crane rails which are installed on top of the crane runway.

Single girder under running – This type of overhead crane is also called underhung and is also ideal for light service situations. The span of this crane should not exceed 60’ with loads of 15 tons or less. This type of crane runs along the bottom flange of the runway beam.

Double girder top running cranes – This type of overhead crane can be used in heavy-duty situations so your load can range from 5-500 tons. The span of this overhead crane can be over 100’. This crane runs along rails installed on top of the crane runway and has two girders. These cranes are more expensive than single girder cranes because of the extra girder. Double girder cranes offer a better hook height than single girder cranes. The reasoning for this is that the trolley hoist sits on top of the crane girder so it allows the hook to rise between the crane girders.

Bridge Girder – Horizontal beam of the crane that supports the trolley and the wire rope hoist. The bridge girder is attached to the crane rail by end trucks.

Crane Rail – Track that is installed on fixed structural steel or concrete beam. The bridge girder travels along this rail by means of end trucks.

Crane Runway – The rails, beams, brackets, and framework on which a crane operates allow it to travel from one end of the building to the other

Wire Rope Hoist – Machinery that is used to lift and lower a load. Click here for more info

Trolley – Carries the hoist which travels on bridge rails allowing it to move from side to side.

End Truck – Supports the bridge girders allowing it to run on the crane rail allowing the crane to move up and down the crane runway. End trucks consist of a frame, wheels, bearings, and axles. Click here for more info

Capacity – The weight of the material being moved.

For a full understanding of our offerings, please visit our Overhead Crane Photo Gallery to view some of our past projects.

Contact us today at 800-431-4223 or sales@aceworldcompanies.com

Interested in us quoting your next project? Please fill out our quote request form and we will get back to you.